Feeds and Speeds for High Speed Machining

and Trochoidal Milling

The curvy spiraling tool paths of high speed machine have radically performance in many cases. At first, the feeds and speeds possible with these toolpaths seem impossible to believe. Then you see it in action and you have to have them, but calculating proper feeds and speeds for them is also exremely difficult. G-Wizard can handle all that for you, no problem.

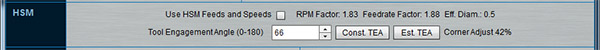

The HSM capabilities of G-Wizard are located at the bottom:

High Speed Machining Feeds and Speeds...

To use it, set up your cut as you normally would, then go down to the HSM section and click the "Const. TEA" button. This will cause G-Wizard to compute your Tool Engagement Angle based on the Cut Width (Stepover) that you have entered. You can see from the RPM Factor and the Feedrate Factor how much faster HSM will allow you to go. In this case, it is showing 1.83x the RPM and 1.88x the Feedrate. Just click "Use HSM Feeds and Speeds" and these values will be factored in--that's all there is to it.

Clearly Cut Width is pretty important to HSM Feeds and Speeds. CADCAM Wizards can be set up to use HSM via the "Roughing Strategy" pulldown. It's useful to do this as HSM is particularly finicky about Cut Width since it determines Tool Engagement Angle. Using CADCAM Wizards, you can find the optimal Cut Width to maximize your HSM power.

Trochoidal Milling

Trochoidal milling is very similar to HSM toolpaths, but its a slightly older technique. You can use the same approach to figure feeds and speeds for it. More information on Feeds and Speeds for Trochoidal Milling is available here.

HSM Without an HSM Toolpath

The big idea behind HSM toolpaths is to avoid slamming the cutter into corners where the Tool Engagement Angle (TEA) goes up radically. Forces on the cutter skyrocket and it is very tough on the cutter. HSM Feeds and Speeds are so much higher because they avoid that. Sometimes we make cuts that don't involve inside corners and the TEA is constant and relatively low. Suppose you're cutting an outside profile around a rectangular boss--there are no inside corners. Or suppose you're helically interpolating a hole? No corners there either.

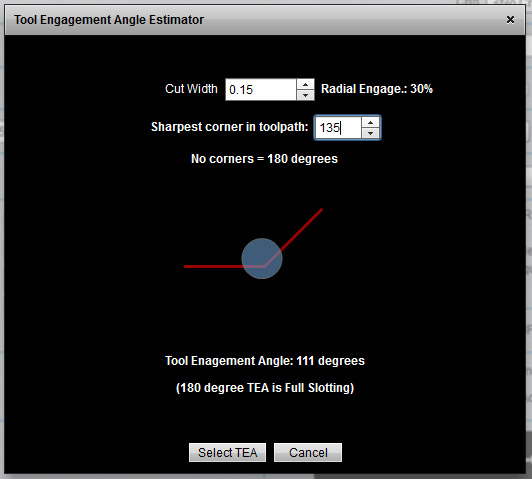

In these cases, if you can estimate the TEA, you could choose to go faster and use HSM Feeds and Speeds. Use the "Est. TEA" button to popup a tool to help you estimate:

Estimate TEA from Cut Width and Corner Angle...

|

Next |